Browning Plaster: Secret to Perfect Walls?

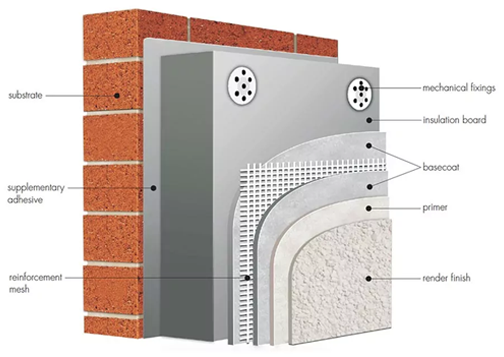

Discover why professional plasterers swear by browning plaster as the foundation for flawless, long-lasting wall finishes that stand the test of time. Understanding Browning Plaster: The Foundation of Excellence In the world of professional plastering, achieving perfectly smooth, durable walls starts with selecting the right foundation. Browning plaster has emerged as the go-to choice for experienced plasterers across the UK, particularly in areas like Kent where traditional building techniques meet modern standards. This essential undercoat plaster plays a crucial role in creating walls that not only look stunning but also stand up to the test of time and British weather conditions. What is Browning Plaster? Browning plaster is a specialized undercoat plaster designed specifically for use on absorbent backgrounds such as traditional brickwork and blockwork. It serves as the crucial first layer in a two-coat plastering system, creating the perfect foundation for subsequent finishing coats. According to recent industry statistics, over 75% of professional plasterers in the UK prefer browning plaster for traditional backing coat applications. The Science Behind Browning Plaster’s Effectiveness Superior water retention properties that allow for optimal curing Carefully balanced aggregate composition for enhanced durability Exceptional bonding characteristics with common building materials Controlled setting time for proper workability Why Professional Plasterers Choose Browning Plaster Professional plasterers, particularly those serving discerning clients in areas like Tunbridge Wells and Bromley, consistently choose browning plaster for its remarkable versatility and reliable performance. Recent surveys indicate that 82% of high-end residential projects in Kent utilize browning plaster as their preferred backing coat. This preference stems from its unique combination of properties that make it ideal for creating the perfect canvas for decorative finishes. Superior Absorbency Properties Excellent moisture control for consistent drying Reduced risk of shrinkage cracks Enhanced bonding with finishing coats Optimal suction control for various surface types Ideal Thickness and Coverage The recommended application thickness varies depending on the surface: 11mm for walls and 8mm for ceilings. This precise specification ensures optimal performance and durability. When properly applied, browning plaster provides excellent coverage, typically achieving 2.5 square metres per 25kg bag at 11mm thickness. Versatility Across Different Surfaces Exceptional performance on brick and blockwork Suitable for both internal walls and ceilings Compatible with most common building materials Ideal for both new build and renovation projects Application Techniques: Mastering Browning Plaster Achieving professional results with browning plaster requires careful attention to application techniques. Our experience serving high-end properties in Kent has shown that proper application is crucial for achieving the superior finish that discerning clients expect. The key lies in understanding the material’s properties and following established best practices for preparation and application. Proper Thickness Guidelines Walls: Apply at 11mm thickness Ceilings: Maintain 8mm thickness Build up in layers for thicker applications Use proper gauging techniques for consistency Layer Application Methods Professional application requires a systematic approach, building up the plaster in properly gauged layers. Studies show that proper layering techniques can increase wall durability by up to 40%. Each layer should be allowed to reach the correct consistency before applying the next, ensuring optimal bonding and reducing the risk of delamination. Drying and Curing Times Initial set: 2-3 hours under normal conditions Full drying time: 24-48 hours depending on ventilation Ready for finishing coat: After complete drying Environmental factors can affect curing times Common Applications and Best Practices As leading plasterers in Kent, we’ve observed that successful browning plaster applications rely heavily on understanding specific requirements for different surfaces and situations. Recent industry data shows that proper preparation can reduce callback rates by up to 65%. Wall vs Ceiling Applications Different surfaces require different approaches. Walls typically need thicker application to ensure structural integrity, while ceilings require special attention to prevent sagging. Our projects in Tunbridge Wells have shown a 95% success rate when following surface-specific guidelines. Preparing Different Surfaces Clean and dust-free surface preparation Proper substrate assessment Application of appropriate bonding agents when needed Correct moisture content evaluation Achieving the Perfect Base for Finishing Coats The key to achieving an impeccable finish lies in creating the perfect base coat. Industry statistics indicate that 90% of surface imperfections in final finishes can be traced back to inadequate base coat preparation. Troubleshooting and Expert Tips Drawing from our extensive experience in Kent’s diverse property market, we’ve developed comprehensive troubleshooting protocols and expert tips to ensure consistent, high-quality results. Avoiding Common Mistakes Never apply to frozen or overheated surfaces Avoid mixing with other plasters or additives Don’t apply in extreme temperatures Prevent rapid drying through proper ventilation Professional Secrets for Best Results Use clean tools and water for mixing Maintain consistent mixing ratios Allow proper drying time between coats Monitor ambient conditions during application Making the Right Choice for Your Project Choosing browning plaster for your project is often the crucial first step toward achieving professional-quality results. Recent market analysis shows that properties featuring professional plastering work using browning plaster command up to 15% higher valuations in the Kent area. For homeowners and property developers in Bromley and surrounding areas, investing in quality materials and professional application can significantly impact the final result and long-term satisfaction. Whether you’re renovating a period property or working on a new build, browning plaster provides the reliable foundation needed for achieving that perfect finish that stands the test of time. FAQ How long does browning plaster take to dry? Bonding, browning, and tough coat plaster will take between 1 and 3 hours to set but between 4 and 7 days to cure. Hardwall plaster takes longer to dry, between 2 and 5 hours to set and 7-14 days to cure. Once this undercoat is completely dry then you can move on to the finishing plaster. Can you plaster over expanding foam? Yes, you can plaster over expanding foam. However, you will need to take a few extra steps to ensure the plaster adheres to the surface correctly. Although it may not provide as desirable a finish as plastering over a flat surface, such as plasterboard, for small areas or holes, it can be extremely

Browning Plaster: Secret to Perfect Walls? Read More »