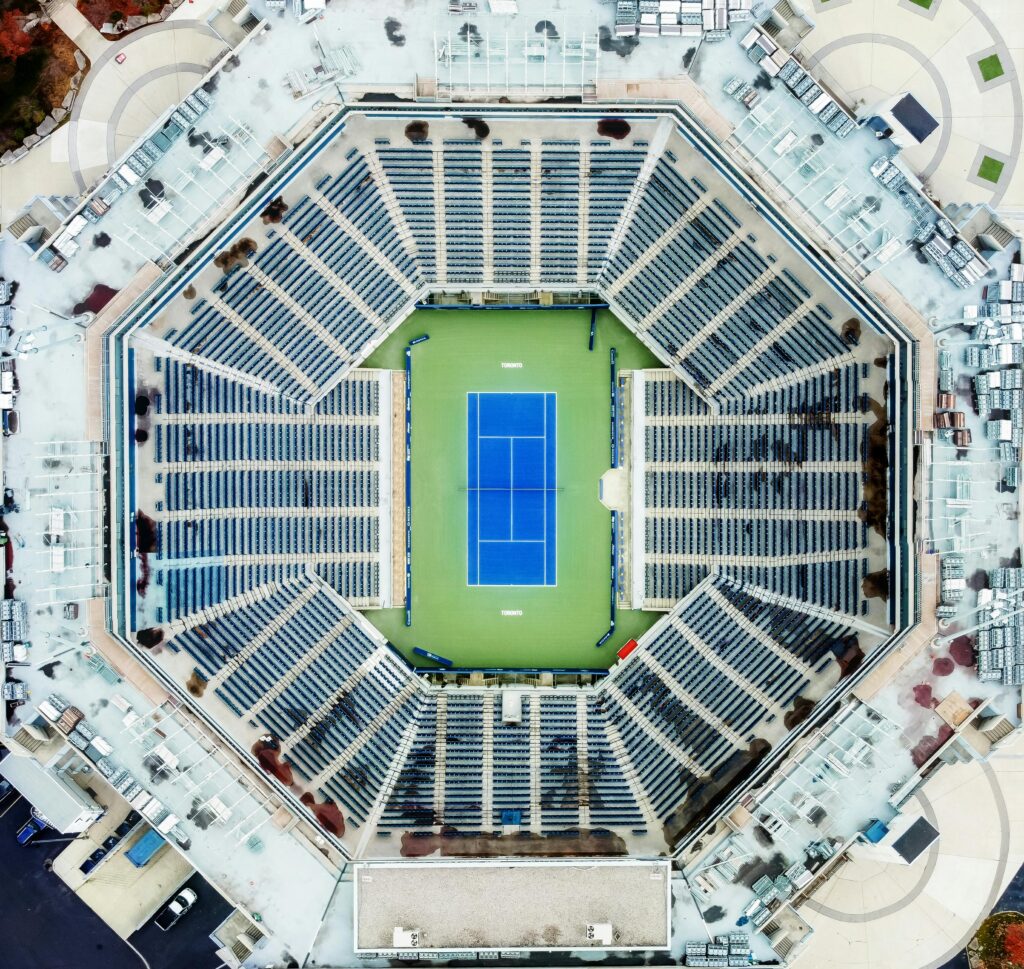

Arthur Ashe Stadium Renovation: Modern Design

Witness the breathtaking transformation of Arthur Ashe Stadium through a groundbreaking renovation that’s redefining tennis architecture. Introduction: A New Era for Tennis Architecture Arthur Ashe Stadium, the crown jewel of the USTA Billie Jean King National Tennis Center, has stood as an iconic symbol of tennis excellence since its inauguration in 1997. Now, a remarkable £650 million ($800 million) renovation project is set to revolutionise this legendary venue. This unprecedented investment, the largest in the tournament’s 145-year history, promises to redefine the tennis experience for both players and spectators alike. The ambitious project, announced by the USTA, marks a pivotal moment in sports architecture, combining innovative design with enhanced functionality to secure the US Open’s position as a premier tennis event for generations to come. The Vision Behind the Transformation The USTA’s vision for Arthur Ashe Stadium extends far beyond mere structural improvements. At its core, this transformation aims to create an unparalleled tennis destination that harmoniously blends architectural excellence with spectator comfort and player convenience. The renovation represents a bold statement about the future of tennis, emphasising the sport’s evolution while preserving its rich heritage. Key objectives include: Enhancing the spectator experience through improved sightlines and premium amenities Modernising player facilities to world-class standards Creating a more sustainable and environmentally conscious venue Establishing a new benchmark for tennis facility design globally Strengthening the US Open’s position as a premier tennis event Expanding the Tennis Experience: Key Architectural Changes The renovation’s most significant architectural modifications focus on maximising the stadium’s potential while maintaining its distinctive character. The cornerstone of these changes is the ambitious expansion of courtside seating from 3,000 to 5,000 seats, remarkably achieved while preserving the total capacity of 24,000 spectators. This engineering feat demonstrates the project’s innovative approach to space utilisation. The addition of eight new premium club areas within the stadium introduces exclusive spaces for enhanced spectator experiences, while the redesigned south entry will create an iconic gateway that befits the tournament’s prestigious status. The Player Performance Center: A Game-Changing Addition A cornerstone of the renovation is the new Player Performance Center, a state-of-the-art four-floor building to be constructed on the west side of the campus. This facility represents a significant upgrade from the current arrangement, where player facilities are housed in the stadium’s underbelly. The new centre will feature: Advanced training and recovery facilities Modern medical and physiotherapy suites Dedicated warm-up and cool-down areas Professional-grade fitness equipment Private consultation rooms and lounges Construction Timeline and Implementation The renovation project adopts a carefully planned three-phase approach, scheduled for completion by the 2027 US Open. This strategic timeline ensures minimal disruption to tournament operations while maintaining the highest standards of construction quality. The phases are structured as follows: Phase 1 (2024-2025): Initial structural modifications and groundwork Phase 2 (2025-2026): Construction of the Player Performance Center Phase 3 (2026-2027): Completion of interior renovations and finishing touches Innovation in Sports Architecture The renovation showcases cutting-edge innovations in sports architecture, setting new standards for facility design. Advanced materials and construction techniques will be employed to enhance both aesthetics and functionality. Key innovative features include: Smart building management systems for optimal energy efficiency Advanced acoustic engineering for improved atmosphere Integrated digital technology for enhanced spectator engagement Sustainable design elements reducing environmental impact The Future of Tennis Venues Arthur Ashe Stadium’s renovation represents more than just a facility upgrade; it’s a blueprint for the future of tennis venues worldwide. The project’s emphasis on sustainability, spectator experience, and player facilities establishes new benchmarks for sports architecture. The economic impact extends beyond the immediate construction phase, creating long-term value through increased revenue opportunities and enhanced global prestige. This transformation will influence future tennis facility designs globally, demonstrating how modern architecture can honour tradition while embracing innovation. Conclusion: Redefining the Tennis Experience The Arthur Ashe Stadium renovation project stands as a testament to tennis’s evolution and the USTA’s commitment to excellence. This transformative investment ensures the US Open’s position at the forefront of tennis innovation while creating an enduring legacy for future generations. As construction progresses towards its 2027 completion, the project promises to deliver a venue that not only meets but exceeds the expectations of players, spectators, and tennis enthusiasts worldwide. For the latest updates on this groundbreaking project, stay tuned to official USTA channels and tennis news outlets. Sources [1] https://www.tennis.com/baseline/articles/first-look-usta-800-million-overhaul-us-open-arthur-ashe-stadium-player-performance-center [2] https://www.sportsbusinessjournal.com/Articles/2025/05/19/ustas-master-plan/ [3] https://www.nyc.gov/assets/designcommission/downloads/pdf/08-12-2024-pres-DPR-p-ArthurAsheStadium.pdf

Arthur Ashe Stadium Renovation: Modern Design Read More »