Venetian Plaster Walls: Installation Guide

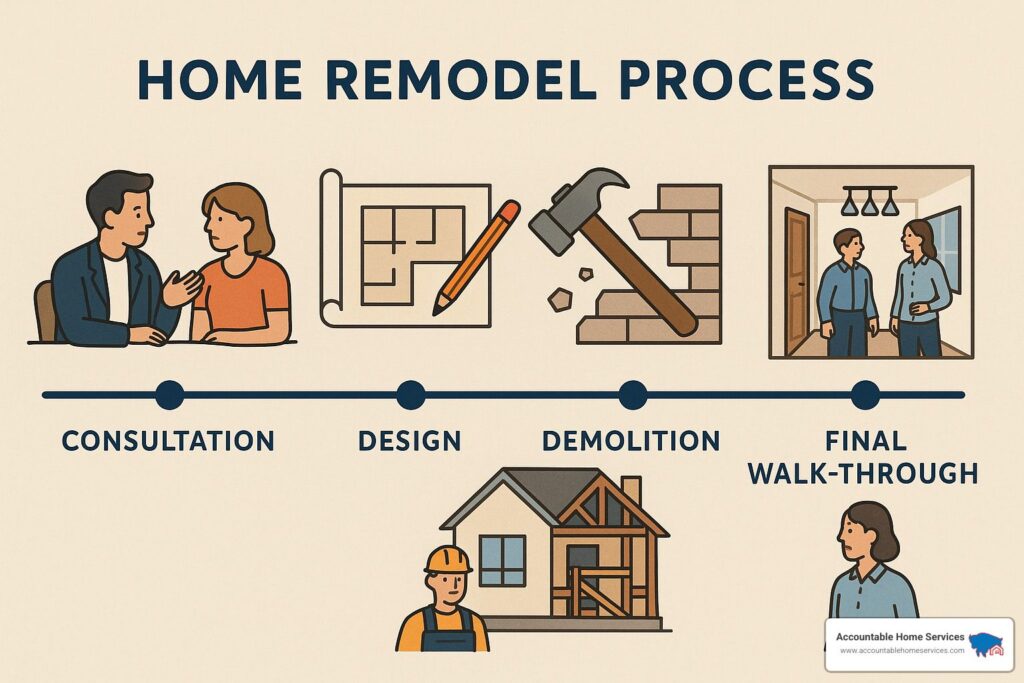

At a Glance: Venetian plaster is a luxurious, durable wall finish with Italian origins dating back over 1,000 years. Made from limestone and marble dust, it creates stunning depth and dimension while lasting 50+ years. Installation costs £80-£150 per square metre in the UK, and properly applied Venetian plaster can increase home resale value by 15-20%. The finish requires minimal maintenance and offers superior breathability compared to standard painted surfaces. Discover how Venetian plaster walls can elevate your living space from ordinary to extraordinary, bringing centuries-old Italian luxury into your modern home. Understanding Venetian Plaster: A Journey Through Time Venetian plaster, known as ‘stucco veneziano’ in Italy, has graced the walls of prestigious buildings for over 1,000 years. This exquisite wall finish originated in Venice during the Renaissance period, where skilled artisans combined slaked lime with marble dust to create surfaces that mimicked the appearance of polished marble. Today, this timeless technique has evolved to meet modern demands while maintaining its luxurious appeal. Recent surveys indicate that the use of Venetian plaster in UK homes has increased by 45% since 2020, as homeowners seek sophisticated alternatives to traditional wall finishes. The Science Behind the Beauty At its core, Venetian plaster is a remarkable blend of natural materials that creates a living, breathing surface. Traditional formulations combine limestone and marble dust with water, creating a compound that undergoes carbonation when exposed to air. This chemical process results in a crystalline structure that provides both durability and visual depth. Modern versions now include advanced acrylic polymers that offer enhanced workability and faster drying times, while maintaining the classic aesthetic. The composition allows for excellent breathability, with studies showing that Venetian plaster walls can help regulate indoor humidity levels by up to 30% more effectively than standard painted surfaces. The Distinctive Features of Venetian Plaster Stunning depth and dimension that creates a three-dimensional appearance Natural variations in colour and texture that cannot be replicated by paint Superior durability with a lifespan of 50+ years when properly maintained Exceptional temperature resistance up to 300°C Environmental benefits including zero VOCs in traditional formulations Natural mould and mildew resistance due to high alkalinity Traditional vs Modern Applications While traditional lime-based Venetian plaster remains the gold standard for authenticity and durability, modern acrylic alternatives have opened up new possibilities for DIY enthusiasts and budget-conscious homeowners. Traditional formulations offer superior breathability and environmental benefits, with studies showing they can absorb up to 40% more CO2 during the curing process. However, acrylic versions provide easier application, faster drying times, and more colour options, making them an excellent choice for contemporary projects. Both options deliver the characteristic lustre and depth that makes Venetian plaster so desirable. Feature Traditional Lime-Based Modern Acrylic Breathability Superior (absorbs up to 40% more CO2) Good Drying Time 24 hours between coats Faster Application Requires expertise Easier for DIY Colour Options Limited natural tones More variety Environmental Impact Zero VOCs Varies by product The Application Process: Artistry Meets Technique Surface Preparation Thorough cleaning and repairs of existing walls Application of specialised primer Creation of smooth, level base coat Application Techniques Multiple thin layers applied with specific trowel patterns 24-hour drying time between coats Careful burnishing to achieve desired sheen Essential Tools High-quality stainless steel trowels Specialised finishing tools Professional-grade materials Pro Tip: Always allow the full 24-hour drying time between coats. Rushing this process can compromise the finish quality and reduce the plaster’s long-term durability. Where to Use Venetian Plaster Venetian plaster’s versatility makes it suitable for numerous applications throughout your home or commercial space. Interior applications shine in living rooms, dining areas, and entrance halls, where the play of light enhances the finish’s natural beauty. Recent architectural trends show a 60% increase in Venetian plaster use in commercial spaces, particularly in high-end retail and hospitality environments. For wet areas like bathrooms and kitchens, special sealers provide additional protection while maintaining the material’s characteristic appearance. Maintenance and Care Maintaining Venetian plaster is surprisingly straightforward, requiring minimal intervention to preserve its beauty. Regular dusting with a soft cloth and occasional cleaning with pH-neutral solutions are typically sufficient. Studies show that properly maintained Venetian plaster can retain its appearance for over 25 years without significant intervention. For high-traffic areas, annual inspection and touch-ups may be necessary to maintain optimal condition. Cost Considerations and Value While the initial investment in Venetian plaster may be higher than traditional wall finishes, its longevity and timeless appeal offer excellent value for money. Current market analysis shows that homes featuring Venetian plaster finishes command a 15-20% premium in resale value. Installation costs in the UK typically range from £80 to £150 per square metre, depending on the complexity of the project and the specific finish chosen. When considering the minimal maintenance requirements and durability, Venetian plaster proves to be a cost-effective luxury investment. Cost Factor Details Installation Cost £80-£150 per square metre Lifespan 50+ years with proper maintenance Maintenance Appearance 25+ years without significant intervention Resale Value Increase 15-20% premium Working with Professional Applicators Essential Qualifications Verified training and certification Extensive portfolio of completed projects Knowledge of both traditional and modern techniques Key Questions to Ask Experience with specific finish types Material preferences and recommendations Project timeline and process details Warranty and aftercare services Conclusion: Bringing Italian Elegance Home Venetian plaster walls represent more than just a wall finish; they’re an investment in timeless elegance and sophistication. Whether you’re renovating a period property or adding character to a modern space, this versatile technique offers unparalleled beauty and durability. Contact Kent Plasterers today to explore how we can transform your walls into works of art that will be admired for generations to come. FAQ Does Venetian plaster crack easily? Venetian plaster is more likely to crack in older homes where there is movement or even subsidence, and especially where the product was applied several decades before. Some of the most common factors that can cause Venetian plaster to crack include: Continuous high winds External vibrations How much does 1000 sq ft of plaster

Venetian Plaster Walls: Installation Guide Read More »