How Does Moisture Resistant Plasterboard Actually Protect Your Walls?

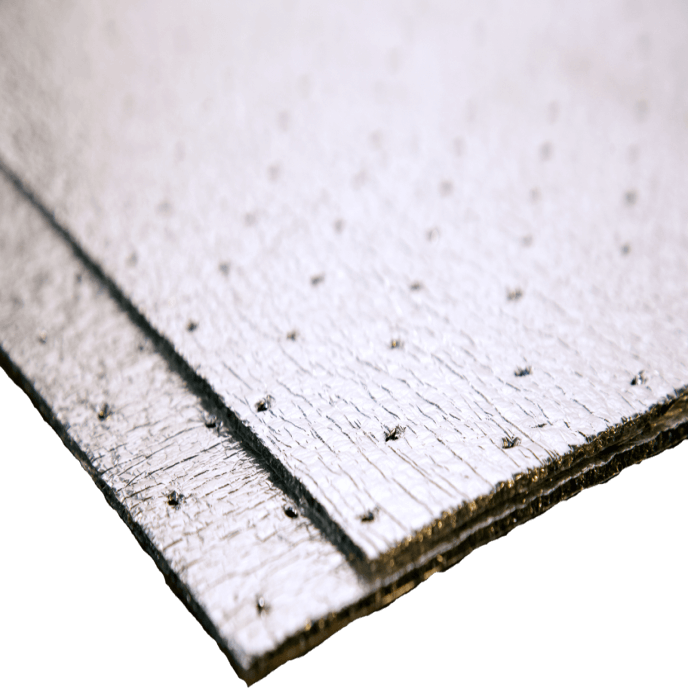

Discover the hidden science behind moisture resistant plasterboard and why it’s the secret weapon for lasting, waterproof walls that professionals swear by When it comes to protecting walls in moisture-prone areas, understanding how moisture resistant plasterboard works is crucial for making informed decisions about your home’s interior. With recent studies showing that up to 85% of bathroom wall damage is caused by inadequate moisture protection, it’s more important than ever to understand the technology that keeps our walls dry and durable. The Science Behind Moisture Resistant Plasterboard Moisture resistant plasterboard, often recognisable by its distinctive green colour, represents a significant advancement in building material technology. Unlike standard plasterboard, this specialised variant incorporates several innovative features that work together to create a robust barrier against moisture. The development of this technology has led to a 40% reduction in moisture-related wall damage in properly protected spaces. Special Core Composition Specially treated gypsum core infused with water-repellent additives Silicone-based compounds that create a hydrophobic barrier Enhanced density structure that reduces water absorption by up to 40% Reinforced core integrity that maintains structural stability when exposed to moisture Advanced binding agents that prevent core deterioration Protective Facing Materials The facing material is crucial to the board’s moisture-resistant properties. Modern moisture resistant plasterboard utilises either specially treated paper or fiberglass mat facing, each engineered to provide superior protection. The facing materials undergo a specialized treatment process that creates a moisture barrier while maintaining breathability, allowing any trapped moisture to safely evaporate rather than accumulate within the board. Key Features and Protection Mechanisms Understanding how moisture resistant plasterboard actively protects your walls involves examining its multi-layered defence system. Recent technological advances have resulted in boards that can resist up to 95% more moisture than standard plasterboard, making them ideal for high-humidity environments. Moisture Barriers Multi-layer water-repellent coating system Integrated vapour barriers that prevent moisture penetration Microscopically engineered surface texture that repels water droplets Capillary-breaking technology that prevents moisture wicking Enhanced edge treatment for comprehensive protection Mold Resistance Properties Modern moisture resistant plasterboard incorporates advanced antimicrobial technology that actively inhibits mold growth. These boards are tested to achieve the highest ratings in standardised mold resistance tests, with studies showing up to 99% reduction in mold growth compared to standard plasterboard. Real-World Performance and Limitations While moisture resistant plasterboard offers superior protection against humidity and occasional water exposure, it’s essential to understand its limitations. This material is water-resistant, not waterproof, and performs best as part of a comprehensive moisture management system. Moisture Resistance vs. Waterproofing Can withstand intermittent moisture exposure but not constant water contact Provides up to 24 hours of protection against casual water exposure Requires additional waterproofing in direct-splash zones Works best in conjunction with proper ventilation systems Should be combined with waterproof membranes in wet rooms Ideal Applications Moisture resistant plasterboard excels in areas with elevated humidity levels and occasional water exposure. Research indicates that proper installation in appropriate locations can extend wall life by up to 15 years. Common applications include bathrooms, kitchens, laundry rooms, and basement areas where moisture control is crucial. Installation and Maintenance Requirements Proper installation is crucial for maximising the effectiveness of moisture resistant plasterboard. Studies show that over 60% of moisture-related failures are due to incorrect installation rather than product limitations. Professional Installation Tips Use moisture-resistant screws and fixings Maintain proper spacing between boards for expansion Seal all joints with water-resistant compounds Apply appropriate primers before decorating Ensure proper ventilation during and after installation Long-term Care Maintaining moisture resistant plasterboard involves regular inspection and prompt attention to any signs of water damage. Proper care can extend the life of your installation by up to 25 years, making it a cost-effective solution for moisture-prone areas. Making the Right Choice for Your Project Selecting the appropriate moisture resistant plasterboard involves considering various factors, including the specific application, environmental conditions, and budget constraints. Recent market analysis shows that investing in quality moisture resistant plasterboard can reduce long-term maintenance costs by up to 40%. Cost vs. Benefits Analysis Initial cost typically 20-30% higher than standard plasterboard Reduced maintenance costs over the product lifetime Lower risk of costly moisture damage repairs Extended durability in moisture-prone environments Improved property value through quality materials Professional Recommendations Expert installers consistently recommend using moisture resistant plasterboard in any area where humidity levels regularly exceed 70%. Statistics show that preventive use of moisture resistant plasterboard can reduce the likelihood of moisture-related repairs by up to 75%, making it a wise investment for long-term property protection. FAQ Can you tile straight on to moisture board? Yes, it is possible to tile directly to our Gyproc moisture resistant (MR) grade boards without any pre-treatment, following the tile adhesive manufacturer’s guidance. Where should you use moisture resistant drywall? Space prone to moisture such as bathrooms and laundry rooms are also typically most prone to mold – which can be disastrous and costly to the structure of your home. Walls and ceilings in these spaces that are often damp due to humidity or splashing are suitable for mold-resistant drywall. Is plasterboard ruined if it gets wet? Generally yes, the board should be removed and replaced with an equivalent Gyproc product to maintain the original performance criteria. How long does moisture resistant plasterboard last? Lifespan: These boards are long-lasting, and when installed according to the correct guidelines, they will last the entire lifespan of the building. Can you paint straight onto moisture resistant plasterboard? Yes, you can paint, plaster, tile or decorate moisture-resistant plasterboard after fitting it – just like standard plasterboard and most other types available. Sources [1] https://www.dunnlumber.com/all-departments/lumber-plywood/plywood-sheetgoods/wallboard-panels/proroc-water-mold-resistant-plasterboard-5-8-inches-with-m2tech-4-feet-x-8-feet-pb58wr.html [2] https://www.buildgp.com/product/toughrock-mold-guard-gypsum-board [3] https://gypsum.org/multi-family-applications-for-specialty-gypsum-board/mold-moisture-resistant-gypsum-panels/

How Does Moisture Resistant Plasterboard Actually Protect Your Walls? Read More »