Kitchen Renovation Costs: Budgeting Guide

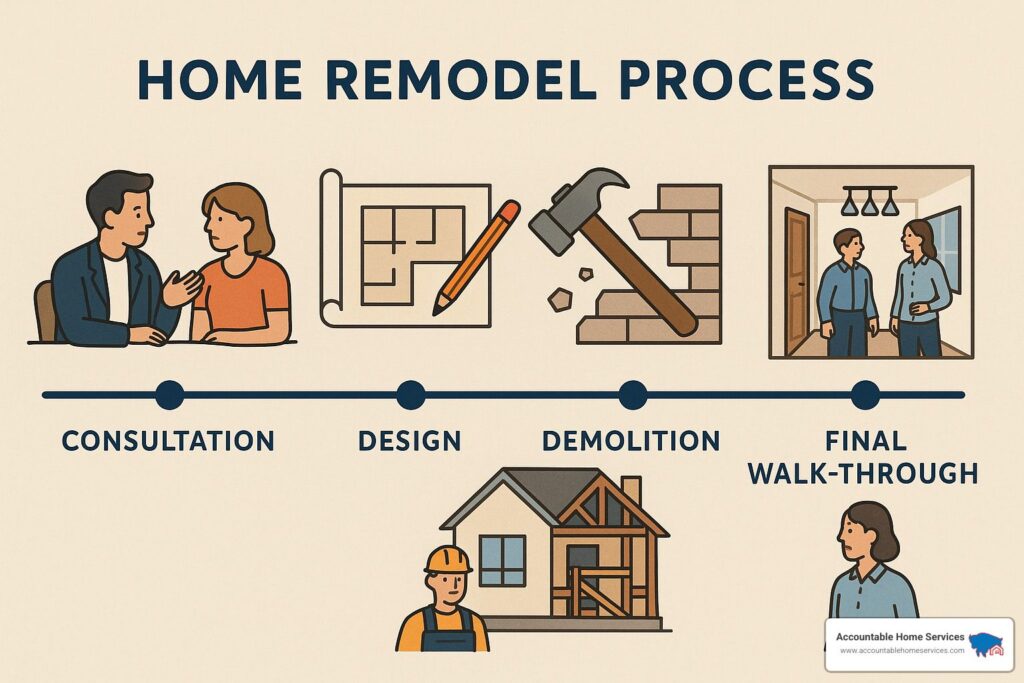

Quick Answer: Kitchen renovation costs in 2026 typically range from £12,000 to £35,000 for mid-range remodels in Kent and Bromley. Minor updates start under £10,000, whilst luxury renovations can exceed £150,000. Your final cost depends on kitchen size, material choices, layout changes, and the scope of work required. Understanding how much it costs to renovate a kitchen is essential before you start planning your dream space and avoid costly surprises. Whether you’re a homeowner in Bromley looking to enhance your property value or a developer working on multiple projects across Kent, having a clear picture of kitchen renovation costs helps you make informed decisions and prevents budget overruns. The average cost to renovate a kitchen in 2026 ranges from £12,000 to £35,000 for mid-range remodelling dependent on scope, materials and location, but the final figure can vary dramatically based on your specific requirements and choices. Kitchen renovations represent one of the most significant investments you’ll make in your property, yet they consistently deliver excellent returns both in terms of property value and quality of life. The kitchen has evolved from a purely functional space into the heart of the modern home, where families gather, entertain guests, and create lasting memories. This transformation has elevated expectations for kitchen design and functionality, making thoughtful budgeting more crucial than ever. For homeowners across Kent and Bromley, understanding the nuances of renovation costs enables you to plan effectively, prioritise spending where it matters most, and work with skilled tradespeople like Kent Plasterers who deliver exceptional results within your budget parameters. Understanding the scope of kitchen renovation costs Kitchen renovation costs vary enormously depending on the extent of work required, and understanding these different levels helps you determine what’s realistic for your budget and property goals. The scope of your project fundamentally shapes every other decision, from contractor selection to material choices, and establishes the framework within which all subsequent planning occurs. Many homeowners underestimate the complexity involved in kitchen renovations, viewing them as straightforward cosmetic updates when in reality they often involve multiple trades, careful sequencing of work, and coordination of numerous elements to achieve a cohesive result. Whether you’re planning a simple refresh to modernise dated finishes or a complete transformation involving structural changes, accurately assessing the scope prevents unrealistic expectations and ensures your budget aligns with your vision. The key distinction lies between cosmetic updates that work within existing layouts and more comprehensive remodels that fundamentally reconfigure spaces, with each approach delivering different results at vastly different price points. Minor kitchen updates and refreshes Minor updates like refinishing cabinets or replacing appliances may cost under £10,000 and can deliver significant aesthetic improvements without major structural work. These projects focus on refreshing existing elements rather than replacing them entirely, making them ideal for homeowners who appreciate their current layout but want to modernise appearances or improve specific functional aspects. Cabinet refacing ranges from £10,000 to £40,000 depending on materials and kitchen size, offering a cost-effective alternative to complete replacement whilst dramatically transforming the room’s appearance. This approach involves replacing cabinet doors and drawer fronts whilst retaining the existing cabinet boxes, significantly reducing both costs and disruption compared to full replacement. Minor renovations might include: Updating worktops Installing new taps and fixtures Replacing flooring Adding a fresh coat of paint to walls and ceilings Professional plastering work by specialists like Kent Plasterers ensures walls provide the perfect canvas for your refreshed kitchen, with smooth, flawless surfaces that enhance the overall finish. For homeowners on tighter budgets or those planning to sell within a few years, these strategic updates deliver excellent value by modernising appearances without the expense and disruption of complete renovation. Mid-scale kitchen remodels Mid-scale remodels are typically £15,000 to £50,000 and represent the most common renovation level for homeowners in Kent and Bromley. These projects strike an excellent balance between investment and transformation, typically involving replacement of major elements whilst potentially retaining some existing features in good condition. A small kitchen remodel averages £10,000 to £20,000 or up to £41,407 for extensive work involving layout changes and quality finishes that significantly enhance both functionality and aesthetics. Mid-scale renovations generally include new cabinetry, updated appliances, replacement worktops, new flooring, improved lighting, and professional finishing work including plastering and tiling. These projects might involve minor layout adjustments such as relocating appliances or removing non-structural walls to improve flow, though they typically work within the existing footprint to control costs. Quality plastering becomes particularly important at this level, as homeowners invest in finishes that will last for years and significantly impact daily enjoyment of the space. Kent Plasterers regularly works on mid-scale kitchen renovations throughout Bromley and Kent, ensuring walls are perfectly prepared for painting or tiling, with attention to detail that elevates the entire project. This renovation level appeals to long-term homeowners seeking to create their ideal kitchen without excessive expenditure, as well as developers looking to add substantial value to properties before sale. Pro Tip: Working within your existing kitchen footprint can save 30-40% compared to projects involving layout changes, making mid-scale remodels an excellent value proposition for most homeowners. Major and luxury kitchen renovations Major renovations with custom cabinets and high-end finishes can cost £50,000 to £150,000 or more, particularly in larger properties or where architectural changes are required. These comprehensive transformations often involve reconfiguring layouts, removing walls, relocating plumbing and electrical services, installing premium materials throughout, and incorporating cutting-edge appliances and technology. Large luxury renovations in major cities such as Los Angeles frequently cost £30,000 to £100,000, with most common projects falling between £50,000 and £75,000 for truly exceptional results. High-end renovations distinguish themselves through attention to detail, bespoke elements, superior materials, and flawless execution across all trades. Custom cabinetry designed specifically for your space maximises storage and functionality whilst reflecting your personal style, whilst premium worktops in materials like Carrara marble or exotic granite create stunning focal points. Luxury projects often include: Integrated appliances Underfloor heating Sophisticated lighting systems with multiple zones Architectural details that elevate the space beyond

Kitchen Renovation Costs: Budgeting Guide Read More »