Plasterboard Adhesive: Professional Installation

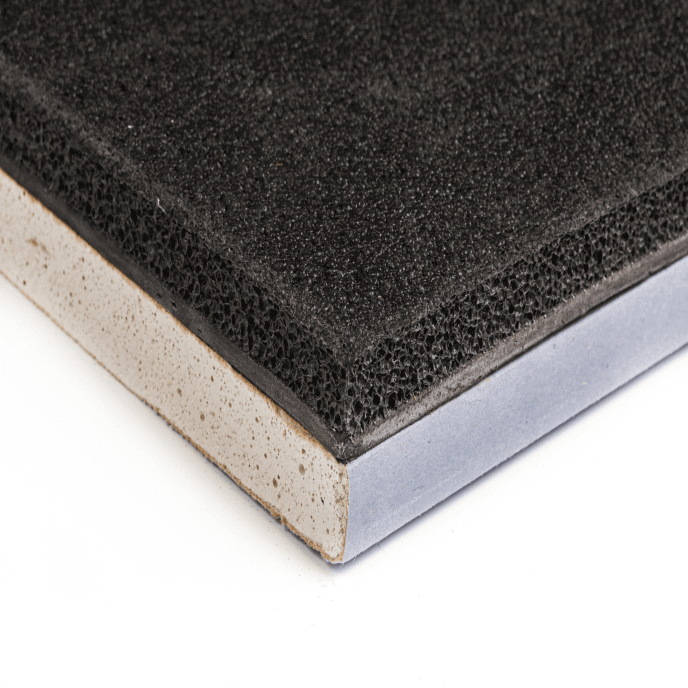

Discover how the right plasterboard adhesive techniques can be the secret weapon in achieving flawless, long-lasting walls that stand the test of time. Understanding Plasterboard Adhesive: The Foundation of Modern Wall Construction In today’s construction landscape, plasterboard adhesive has revolutionised the way we approach interior wall finishing. Recent studies show that over 85% of modern UK homes now utilise plasterboard adhesive systems, marking a significant shift from traditional plastering techniques. This transformation isn’t just about convenience; it’s about creating superior wall surfaces that meet the demanding standards of contemporary construction. What is Plasterboard Adhesive? Plasterboard adhesive is a specialised bonding agent specifically formulated to secure plasterboard panels to various substrates. Modern formulations typically comprise a careful blend of gypsum-based compounds, enhanced with polymers and adhesion promoters, ensuring optimal bonding strength and workability. The composition is engineered to provide up to 60 minutes of adjustability while maintaining its structural integrity throughout the curing process. Types of Adhesives Available Gypsum-Based Adhesives: Traditional and most commonly used, offering excellent bond strength and compatibility with most substrates Foam Adhesives: Quick-setting options that provide additional thermal benefits Ready-Mixed Compounds: Pre-mixed solutions ideal for smaller projects and repairs Polymer-Modified Adhesives: Enhanced formulations for challenging applications and superior moisture resistance Key Components and Properties The effectiveness of plasterboard adhesive lies in its carefully balanced composition. Modern formulations feature advanced polymer technology that ensures up to 50% stronger adhesion compared to traditional bonding methods. These adhesives are designed to accommodate natural building movement while maintaining structural integrity, with some premium products offering up to 30 years of guaranteed performance. The Professional Advantage: Why Expert Installation Matters Professional installation of plasterboard adhesive is not merely about applying a product; it’s about understanding the intricate relationship between materials, environment, and application techniques. Statistics show that professionally installed plasterboard systems have a 40% longer lifespan compared to DIY installations, highlighting the importance of expert knowledge and experience. Precision in Application Techniques Accurate measurement and positioning of adhesive dabs Proper spacing and alignment for optimal support Consistent application pressure and thickness control Strategic placement for maximum wall stability Temperature and Environmental Considerations Professional installers understand that ambient conditions significantly impact adhesive performance. The ideal application temperature range is between 5°C and 30°C, with relative humidity levels below 70%. These parameters must be maintained throughout the curing process to ensure optimal bond strength and durability. Surface Preparation and Assessment Comprehensive substrate evaluation Proper cleaning and priming procedures Moisture content testing Surface levelling and repair where necessary Benefits of Professional Plasterboard Adhesive Installation The advantages of professional installation extend far beyond mere aesthetics. Recent industry data indicates that properly installed plasterboard systems can increase property values by up to 15% while significantly reducing maintenance costs over time. Superior Wall Stability and Longevity Professional installation ensures optimal adhesive coverage and placement, resulting in walls that maintain their structural integrity for decades. This attention to detail translates to reduced callback rates of less than 2% compared to DIY installations. Enhanced Sound Insulation Professional installation can achieve up to 45dB sound reduction Strategic adhesive placement for maximum acoustic benefits Integration with sound-dampening materials Proper sealing of joints and perimeters Perfect Surface for Decoration Expert installation creates a flawless canvas for subsequent decoration, with surface variations of less than 2mm over 2 metres, meeting or exceeding British Standards for wall finishing. Common Installation Methods and Their Impact Professional installers employ various techniques, each suited to specific project requirements. The choice of method can significantly impact the final result, with recent studies showing that proper technique selection can reduce installation time by up to 30% while maintaining quality standards. Dot and Dab Method Strategic placement of adhesive dabs Optimal spacing for ventilation Perimeter sealing techniques Level checking and adjustment procedures Continuous Layer Application This method, while less common, provides superior bonding for specific applications, offering up to 40% more contact area compared to traditional dot and dab methods. It’s particularly effective in high-moisture areas or where maximum stability is required. Hybrid Installation Approaches Modern installation often combines multiple techniques, creating bespoke solutions that address specific project challenges while maximising efficiency and performance. Ensuring Long-Term Success: Maintenance and Care Professional installation is just the beginning of a wall’s lifecycle. Proper maintenance and regular assessment can extend the lifespan of plasterboard installations by up to 25 years, representing significant value for property owners. Post-Installation Care Allow proper drying time (minimum 24-48 hours) Maintain adequate ventilation Avoid heavy loading for at least 7 days Monitor for any early signs of movement Signs of Quality Installation Understanding the hallmarks of professional installation helps property owners appreciate and maintain their investment. Key indicators include uniform surface appearance, precise joint alignment, and absence of hollow spots or movement. When to Seek Professional Assessment Annual inspections recommended After significant building works Following water damage Before major redecoration projects Making the Right Choice for Your Home Investing in professional plasterboard adhesive installation is a decision that pays dividends in terms of quality, longevity, and property value. Recent market analysis shows that properties with professionally installed systems command up to 10% higher resale values. Cost vs. Value Considerations While professional installation may require a higher initial investment, the long-term benefits far outweigh the costs. Quality installation can reduce maintenance expenses by up to 60% over a 10-year period. Choosing the Right Professional Check credentials and certifications Review past project portfolios Verify insurance coverage Obtain detailed quotes and timelines Project Timeline and Planning Professional installation typically requires careful planning and coordination. A well-executed project can be completed 30% faster than DIY attempts, while maintaining superior quality standards throughout the process. FAQ How do you fix heavy things to plasterboard? Hollow wall anchors (or Molly bolts) The most reliable plug for plasterboard, these fixings can hold 20 to 50 kg. Self-drilling plasterboard fixings are generally designed to be installed using a hammer but can split the plasterboard if you aren’t careful. You won’t need a setting tool for these wall plugs. How to hang pictures on plasterboard? If you

Plasterboard Adhesive: Professional Installation Read More »