Selecting the right plaster scraper can make the difference between a smooth, professional finish and hours of unnecessary labor – here’s what the experts don’t tell you.

Understanding Plaster Scraper Basics

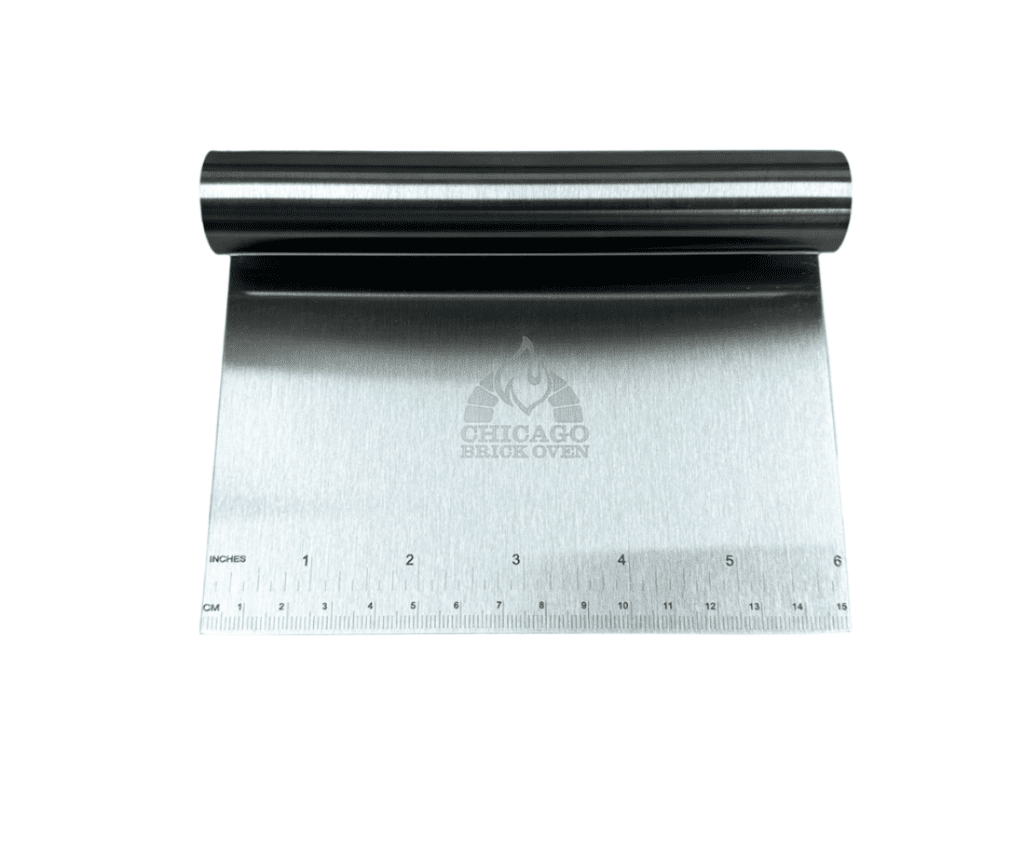

A plaster scraper is more than just a simple tool; it’s a crucial instrument that can significantly impact the quality of your plastering work. As professional plasterers in Kent with over 15 years of experience, we’ve learned that understanding the fundamental components of a quality plaster scraper is essential for achieving professional results. These tools are designed specifically for smoothing and shaping plaster surfaces, but their versatility extends to various applications in construction and renovation work. The basic anatomy of a plaster scraper consists of a blade and handle, but it’s the quality and design of these components that separates professional-grade tools from basic alternatives.

Blade Materials and Construction

Carbon steel blades are the industry standard for professional plaster scrapers, and for good reason. These blades offer superior durability and maintain their edge longer than cheaper alternatives. High-quality carbon steel blades can last up to 3 times longer than standard stainless steel versions when properly maintained. The blade’s thickness typically ranges from 0.5mm to 2mm, with thicker blades providing more rigidity for heavy-duty work. The best blades feature:

- Heat-treated carbon steel for enhanced durability

- Precision-ground edges for consistent performance

- Rust-resistant coating for longevity

- Uniform thickness across the entire blade

- Proper tempering to prevent brittleness

Handle Types and Ergonomics

The handle of a plaster scraper plays a crucial role in both comfort and control. Wooden handles remain the preferred choice among professional plasterers, particularly those made from hardwoods like beech or ash. Research shows that wooden handles reduce hand fatigue by up to 40% compared to plastic alternatives. Consider these key aspects of handle design:

- Ergonomic grip patterns for reduced strain

- Moisture-resistant treatment for durability

- Balanced weight distribution for better control

- Secure blade mounting systems

- Comfortable length for extended use

Essential Features to Consider

When selecting a professional-grade plaster scraper, several key features distinguish superior tools from basic models. The most crucial aspects include blade width options, flexibility, and overall construction quality. Professional plasterers typically invest in multiple scrapers with different specifications to handle various tasks effectively. Understanding these features ensures you’ll select the right tool for your specific needs.

Blade Width Options

The width of your plaster scraper significantly impacts its functionality and application range. Available widths typically range from 20mm to 120mm, with each size serving specific purposes:

- 20-40mm: Detail work and corners

- 50-75mm: General purpose and medium-sized areas

- 80-120mm: Large surface areas and initial spreading

Blade Flexibility and Rigidity

Different plastering tasks require varying degrees of blade flexibility. Modern scrapers often feature varying flexibility options to accommodate different surface types and plaster conditions. Professional-grade flexible blades can bend up to 15 degrees without permanent deformation, making them ideal for curved surfaces and detailed work.

Choosing the Right Scraper for Different Applications

Selecting the appropriate scraper for specific tasks ensures optimal results and efficiency. Professional plasterers typically maintain a collection of scrapers with different specifications to handle various applications effectively. Understanding how different scrapers perform in specific scenarios is crucial for achieving professional-quality results.

Wall and Ceiling Work

Vertical and overhead plastering requires specific tool characteristics for optimal results:

- Lightweight scrapers for reduced arm fatigue

- Wider blades (80-120mm) for efficient coverage

- Enhanced grip features for secure handling

- Balanced weight distribution for better control

Detailed and Finishing Work

Fine detail work demands precision tools with specific features:

- Narrow blades (20-40mm) for intricate areas

- Flexible blades for curved surfaces

- Sharp, well-maintained edges for smooth finishes

- Ergonomic handles for precise control

Maintenance and Care

Proper maintenance of your plaster scraper is essential for ensuring consistent performance and longevity. Regular maintenance can extend tool life by up to 50% and maintain optimal performance throughout its lifespan. Professional plasterers understand that well-maintained tools not only perform better but also provide more consistent results.

Cleaning and Storage

Implementing proper cleaning and storage practices is crucial:

- Clean thoroughly after each use

- Store in a dry environment

- Apply light oil coating to prevent rust

- Use blade guards when not in use

- Keep tools organized and easily accessible

When to Replace Your Scraper

Knowing when to replace your plaster scraper is crucial for maintaining professional standards. Look for these signs:

- Visible blade wear or damage

- Reduced flexibility in flexible blades

- Handle damage or loosening

- Inconsistent performance

- Rust or corrosion development

Professional Recommendations

Based on our extensive experience in the Kent plastering industry, we recommend investing in quality tools that will deliver consistent results and stand the test of time. Professional-grade scrapers typically last 3-4 times longer than budget alternatives, making them a cost-effective choice for serious plasterers.

Top Brands and Models

- Marshalltown Pro Series

- OX Tools Professional

- Stanley Professional Grade

- NELA Premium Series

- Kraft Tool Elite Series

Investment Considerations

When evaluating plaster scrapers, consider these investment factors:

- Initial cost vs. longevity

- Warranty coverage

- Availability of replacement parts

- Brand reputation

- Local supplier support

Making Your Final Selection

Choose your plaster scraper based on your specific needs, working conditions, and budget. Consider starting with a versatile mid-width scraper (60-75mm) if you’re new to plastering, and expand your collection as needed. Remember that investing in quality tools pays dividends in terms of work quality and efficiency. For professional advice on selecting the perfect plaster scraper or any other plastering needs in Kent, don’t hesitate to contact our experienced team at Kent Plasterers.

FAQ

Does vinegar remove plaster?

Since vinegar is acidic, it quickly dissolves water stains, plaster, and mold buildup. How to use : Mix white vinegar with warm water in a bowl. Pour the solution into a spray bottle and spray it onto the affected area.

How to remove plaster from hand at home?

Water. You can you can soak it off with warm water and vinegar i’ve even been told. And read that you can soak it off with a warm water and fabric softener.

What is the least painful way to remove a plaster?

Lubricate it: Cover the plaster with baby oil, then soak some cotton wool in the same substance before rubbing it over the plaster until you can slowly peel off the corners.

How to easily remove plaster?

Rub oil or lotion over the plaster and then apply some of the same substance to a cotton wool bud. As you slowly lift the corners of the plaster, continue to rub the oil or lotion on the skin underneath to loosen the adhesive. Any lotion or oil, such as baby oil or even olive oil, will work.

Sources

[1] https://www.fauxbrushes.com/products/twi-25-spatula-plaster-scraper-co-me-carbon-steel

[2] https://oleaspecialtyproducts.com/collections/tools

[3] https://www.bontool.com/scratchers-rasps-scrapers